|

| For Spring

DSR's Stainless Steel Wire for Spring is supplying the Products with excellent mechanical properties (advanced surface, cast & helix) for a uniformity of goods following spring wire shape under the strict quality control with our technology from wire rod to final products, fulfilled with suitable coated treatment classified by the usages.

| |

| |

| ● Surface Finish & Applications |

| Type |

Symbol |

Grade |

Dia(mm) |

Applications |

| S-CO |

WPA |

AISI 302, 304, 304N1, 316 |

0.20 ~ 7.00 |

일반 스프링용 |

| WPB |

AISI 302, 304, 304N1 |

0.20 ~ 6.00 |

| WPC |

AISI 631J1 |

0.20 ~ 4.00 |

| Bright |

WPA |

AISI 302, 304, 304N1, 316 |

0.15 ~ 7.00 |

광택이 필요한 Forming 가공

및

스프링용 |

| WPB |

AISI 302, 304, 304N1 |

0.15 ~ 6.00 |

| Ni-Co |

WPA |

AISI 302, 304, 304N1, 316 |

0.20 ~ 1.60 |

정밀 스프링용

고속자동 COIL용 |

| WPB |

AISI 302, 304, 304N1 |

| WPC |

AISI 631J1 |

| Ni-Co Bright |

WPA |

AISI 302, 304, 304N1, 316 |

0.15 ~ 1.60 |

| WPB |

AISI 302, 304,

304N1 | |

| |

| ● Mechanical Properties |

| Dia(mm) |

Tolerance

(mm) |

Tensile Strength N/mm2(kgf/mm2) |

| CLASS A |

CLASS B |

CLASS C |

| AISI 302 - WPAAISI 304 - WPAAISI 316

- WPA |

AISI 302 - WPBAISI 304 - WPB |

AISI 631J1-WPC |

| 0.16 |

±0.005 |

1650 - 1900 |

2150 - 2400 |

1950 - 2200 |

| 0.18 |

| 0.20 |

| 0.23 |

±0.008 |

1600 - 1850 |

2050 - 2300 |

1930 - 2180 |

| 0.26 |

| 0.29 |

| 0.32 |

| 0.35 |

| 0.40 |

| 0.45 |

±0.010 |

1950 - 2200 |

1850 - 2100 |

| 0.50 |

| 0.55 |

| 0.60 |

| 0.65 |

1530 - 1780 |

1850 - 2100 |

1800 - 2050 |

| 0.70 |

| 0.80 |

| 0.90 |

±0.015 |

| 1.00 |

| 1.20 |

1450 - 1700 |

1750 - 2000 |

1700 - 1950 |

| 1.40 |

| 1.60 |

1400 - 1650 |

1650 - 1900 |

1600 - 1850 |

| 1.80 |

±0.020 |

| 2.00 |

| 2.30 |

1320 - 1570 |

1550 - 1800 |

1500 - 1750 |

| 2.60 |

| 2.90 |

1230 - 1480 |

1450 - 1700 |

1400 - 1650 |

| 3.20 |

| 3.50 |

±0.030 |

| 4.00 |

| 4.50 |

1100 - 1350 |

1350 - 1600 |

- |

| 5.00 |

| 5.50 |

| 6.00 |

| 6.50 |

±0.035 |

1000 - 1250 |

- |

| 7.00 | |

| |

| ● Packing |

|

|

| Dia(mm) |

Packing (F X B X W : A) |

App. W/T(kg) |

| 0.16 ~ 0.44 |

DIN 200 |

12 |

| DIN 250 |

20 |

| DIN 355 |

40 |

| SH390 |

15 |

| SH460 |

35 |

| SH460 |

35 |

| 0.45 ~ 0.79 |

400x300x200(60) |

50 |

| 450x300x240(60) |

100 |

| 700x380x250(60) |

250 |

| 0.80 ~ 1.59 |

500x400x300(60) |

100 |

| 600x400x390(60) |

300 |

| 700x380x250(60) |

350 |

| 1.60 ~ 1.90 |

500x400x300(60) |

100 |

| 600x400x390(60) |

300 |

| 700x380x250(60) |

350 |

| 1.91 ~ 4.00 |

500x400x300(60) |

100 |

| 600x400x390(60) |

300 |

| 750x380x480(130) |

500 | |

| |

| Dia(mm) |

Coil I.D (Inch) |

App. W/T(kg) |

| 0.20 ~ 0.30 |

8 |

10 |

| 0.30 over ~ 0.40 |

8 |

10 |

| 0.40 over ~ 0.50 |

8 ~ 10 |

10 |

| 0.50 ~ 0.80 |

12 |

20 ~ 25 |

| 0.80 ~ 0.90 |

16 |

25 ~ 35 |

| 0.90 over ~ 1.00 |

16 |

25 ~ 50 |

| 1.0 over ~ 1.80 |

16 |

25 ~ 50 |

| 1.80 over ~ 2.30 |

24 |

100 |

| 2.30 over ~ 4.00 |

24 |

100 ~ 200 |

| 4.00 over ~ 7.00 |

24 |

200 ~

500 | |

| |

| Dia(mm) |

Coil I.D (Inch) |

App. W/T(kg) |

| 1.91 ~ 7.00 |

24 |

910 | |

| |

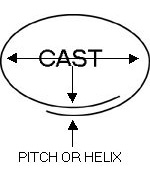

| ● CAST & HELIX(PITCH) |

| The most important thing to make high quality spring is how to control cast

& helix. As our specifications are based on lots of customer's demands, we

have ever made control of it as follows: |

| |

|

|

| Dia(mm) |

Coil I.D(Inch) |

Cast(mm) |

Helix(mm) |

| 0.20 ~ 0.40 |

8 |

200 ~ 300 |

30 under |

| 0.40 over ~ 0.50 |

8 |

200 ~ 300 |

| 10 |

250 ~ 370 |

| 0.50 ~ 0.80 |

12 |

300 ~ 450 |

| 0.80 ~ 0.90 |

16 |

400 ~ 600 |

| 0.90 over ~ 1.00 |

50 under |

| 1.00 over ~ 1.80 |

| 1.80 over ~ 2.30 |

24 |

600 ~ 900 |

60 under |

| 2.30 over ~

7.00 | | |